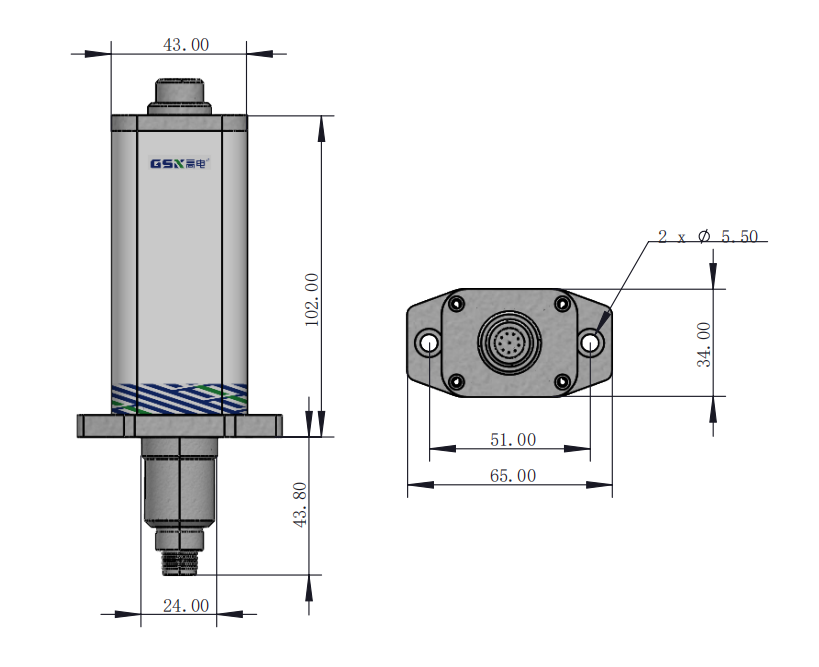

S Servo screwdriver for automatic machine

1, high-precision torque control, torque accuracy of ±3% - ±5%;

2, the use of high-end imported motor, long product life, maintenance-free;

3, accurate float height/slip detection, feedback to PLC or control card for abnormal treatment;

4, accurate tooth detection function to ensure the accurate start of the tightening signal;

5. The lock payment results can be traced, exported and uploaded to the MES system;

6, 16 kinds of tightening tasks, each task supports 5 tightening steps, disassembly task supports 2 disassembly steps, to ensure high controllability of tightening disassembly process;

7, support RS232/485 Modbus RTU communication protocol, strong scalability, support multiple IO input/output, non-standard customized TCP/IP network port, can quickly build intelligent lock payment system;

8, simple installation, easy debugging, provide secondary development interface and technical support.